Maximizing the efficiency of production processes

Free consultation: +38(067) 577 13 75

Automation of the Bakery Production Line: Conveyors and Circulating Table for "Ukrainian Bakery House" LLC

Modernizing bakery production: automated bread and baguette conveyors, accumulating circulating table. High productivity, hygiene, and efficiency for continuous operation.

Video review

Automating the Transportation of Bakery Products in Production

Implementation of Conveyors and a Circulating Table in the Bakery Line

To enhance the efficiency and productivity of bakery operations at "Ukrainian Bakery House" LLC, an automated system for product transportation has been implemented. This system includes conveyors for bread and baguette selection as well as an accumulating circulating table for optimized logistics.

Production Line Specifications

The bakery operates two main production lines:

- Ukrainian Bread Production Line:

- Diameter: 220 mm

- Height: 65 mm

- Weight: 0.95 kg

- Productivity: 900 kg/hour

- Product temperature: 75-90°C

- Baguette Production Line:

- Dimensions: 325×140×80 mm

- Weight: 0.45-0.65 kg

- Productivity: 1150 kg/hour

- Product temperature: 75-90°C

The equipment operates 24/7, requiring high durability and reliability in all components.

Manufacturing and Installation of the Conveyors

Design and Materials

To ensure seamless transportation, the system features stainless steel conveyors equipped with polyurethane and modular plastic belts. These materials provide:

- Compliance with hygiene and food safety standards

- Resistance to high temperatures

- Durability and corrosion resistance

- Ease of sanitation and maintenance

Functions of the Conveyors

- Collecting baked goods after the oven

- Transporting bread and baguettes to the accumulating circulating table

- Automating the stacking and sorting process

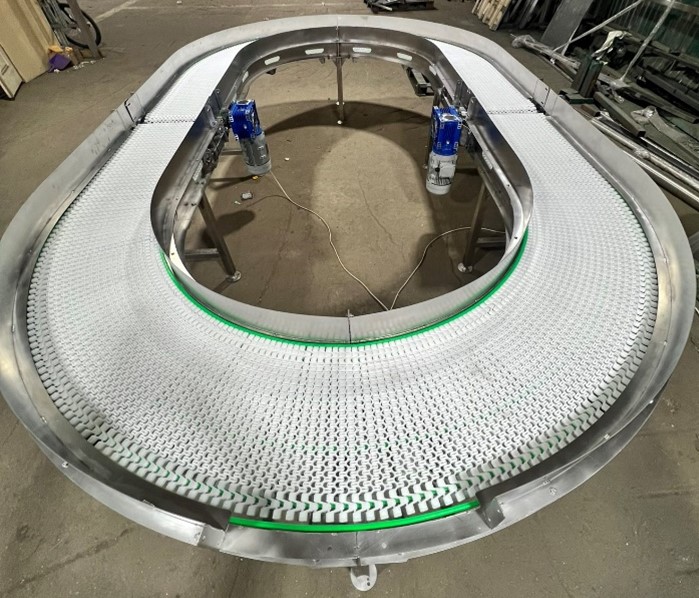

Accumulating Circulating Table – Optimizing Workflow

The circulating table ensures smooth and even distribution of bakery products, facilitating efficient packaging and handling.

Key Benefits of the Circulating Table:

Reduces production bottlenecks

Optimizes product flow and logistics

Ensures a steady production pace

Enhances overall line efficiency

Safety and Sanitary Compliance

Maintaining strict hygiene and safety standards is a top priority. The system is equipped with:

- Bactericidal lamps for disinfection

- Protective covers on conveyors to prevent contamination

- Easy sanitation capabilities to meet food industry standards

Advantages of Bakery Production Automation

Reduced labor costs – minimizing manual handling

Increased productivity – faster processing speeds

Optimized workspace – efficient use of production areas

Compliance with modern hygiene and safety regulations

Automating the transportation and handling of baked goods is key to improving efficiency and ensuring high-quality production.

Conclusion

The implementation of an automated bread and baguette transportation system at "Ukrainian Bakery House" LLC has significantly streamlined production, increased output, ensured compliance with hygiene regulations, and enhanced product quality.

Automated bread conveyors

Accumulating circulating table

Hygienic and safe operations

Maximum efficiency for high-demand production

Cutting-edge solutions for a modern and efficient bakery!